There needed to be an access port in the back for the electronics and wires. A circular recess was routed out, and a lid was made to fit into it.

The lid has a small lip around it to overhang the routed edge in the body. The lip is secondary piece of 2-ply veneer added to the disk of wood.

Here it is in place.

Next a hole was cut big enough to hold the volume knob. Then a little hole was drilled for it to poke through the face on the other side.

It also has extra space around the volume knob so wires can be crammed around it.

There it is protruding out of the face.

The next step was to make worm holes connecting all the components to this chamber. This hole leads to the pickup slot.

It comes out here. See that big ol' hole? Even though the wires are thin it will be a lot easier to wire it up if the hole is ridiculously huge.

Size comparison to a wiener dog.

Also it needed a hole leading to the bridge so a ground wire could be ran to it. That was a smaller target so I made crosshairs with a pencil. Then I'd have an idea as to which direction I should drill.

Woohoo! I was sort of expecting my drill bit to bottom out and never connect to anything, or poke through the middle where the laminated strips are running, but it worked.

Then a slot was cut out for the jack plate. I was stumped as how the jack plate should run in the last guitar post, but since then I've made the painful decision. I hope I don't regret later. It's too late now. It's just wood so the worst that could happen is I'd have to glue in a patch and do something different. I don't think it'll be too bad though like this.

And since there's a jack plate there needs to be another worm hole leading to it. This chamber sure did get worm-holey fast.

POP! There it is! And that's it!

Oh, wait. One more step. Holes were drilled in the lid to attach it to the body.

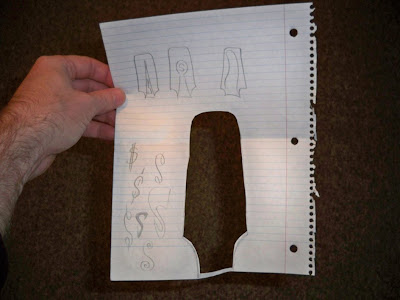

Since the holes aren't measured at exact quadrants and I don't want to accidentally forget and try to align the wrong holes with the wrong holes I made myself a secret note.

Since it's Winter Lucy likes to do this a lot. She pulls the blanket out of her bed and drags it over to where everybody is gathered, and then grunts and squirms and wriggles until she's gotten herself under it. Notice she's in a different blanket than the one up a few pictures. That's because she vomited in that earlier one. She gets sooooo comfortable in her blanket she's not willing to get up and vomit somewhere else. Nice, huh? It's hard to get mad at her though. She's old.

Sometimes she covers up completely and I forget she's there. I can't count how many times I've tripped over a lump like this.

Believe it or not, I think I'm actually done with all the woodworking on this guitar project. All that's left now is staining, lacquering and then soldering the components together.